In food-and-beverage, pharmaceutical and cosmetic-manufacturing applications, Mouvex® Product Recovery refers to the high utilization (or yield) of products or ingredients substantially eliminating waste – and thereby increasing profits – that would otherwise remain in suction or discharge process lines during changeovers or at the end of production runs. Too often, these fluids that remain in the piping, which can be some of the most expensive in the world, are just washed out and flushed down the drain. Or, they’re recovered only with the assistance of costly add-on components, such as pigging systems. But there is a better option available

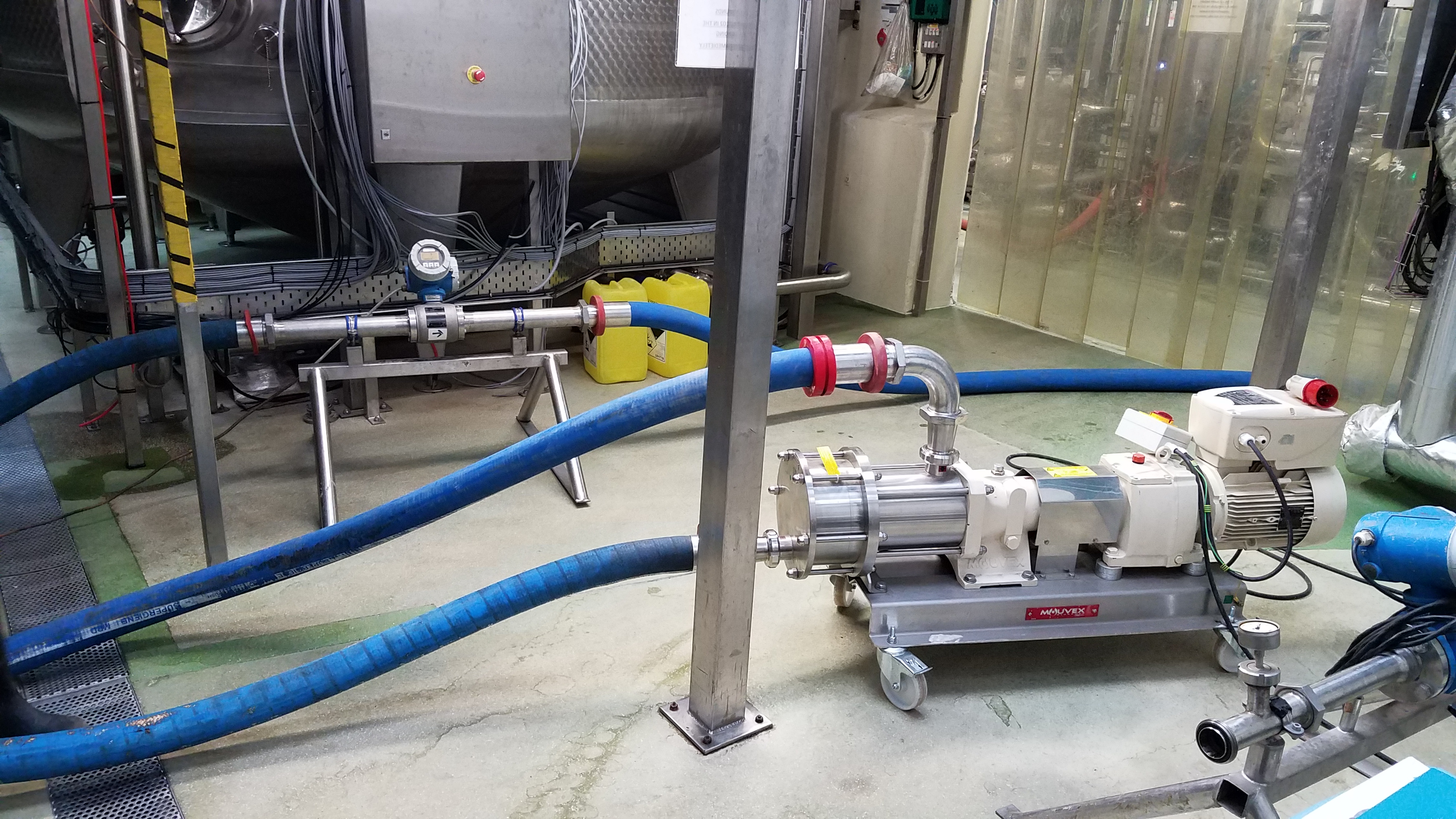

The Mouvex®Advantage. The key to optimising Product Recovery and, by extension, profit recovery is identifying and employing the most efficient and reliable pumping technology, one that can be trusted to reliably strip suction or discharge lines of valuable raw materials and saleable end-products. Eccentric Disc Pump technology from Mouvex® has stood ready to optimize Product Recovery rates thanks to an operating principle that provides non-pulsing, low-slip operation with high volumetric consistency. Mouvex pumps are also able to pump air, which creates a vacuum effect on the pump’s suction side and a compressor effect on the discharge side, which produces a plug effect that pushes a complete product “plug” out of the piping.

How It’s Done.

The unique eccentric disc operating principle from Mouvex features a disc that moves on an eccentric plane within a circular channel. In addition to the operational advantages inherent in this type of pump operation, eccentric disc pumps provide flow rates that vary minimally with changes in viscosity, temperature, system back-pressure and component wear. The result is typical Product Recovery rates of 60% to 80% when compared to other technologies like lobe or external circumferential piston pumps. Find out how much you can save. Download the Recovery Calculation Worksheet.

The Mouvex® SLS Series Eccentric Disc Pump sets a new standard in efficiency and reliability in hygienic product transfer. No other pump can claim this collection of features and benefits for the hygienic industry:

No Slip, even when pumping air

No mechanical seals means no leaks

No pulsation for flow consistency

Clean-in-Place (CIP)

Certifications

To understand how the Mouvex SLS pump achieves this highly efficient performance, watch this animation of the Eccentric Disc Principle.

What is the Value of Product Recovery?

The following chart illustrates a conservative example of how much money, in general, a food and beverage, pharmaceutical or cosmetic manufacturer can save through the use of pumping technology that is able to achieve increased product-recovery rates around 60% to 80%.